Water Cooled Capacitors (Medium Frequency) Manufacturer

Water Cooled Capacitor, Medium Frequency Water cooled Capacitor, High Frequency Water cooled Capacitor, Capacitors Manufacturer, Exporter in Kolhapur, India

Water-cooled capacitors are one of the essential components used in high-power electronics and electrical systems. These capacitors are designed to handle high voltages and currents, making them suitable for use in various applications such as welding machines, high-frequency heating equipment, and induction heating systems.

Types of Water-Cooled Capacitors

1) Medium-Frequency Water-Cooled Capacitor

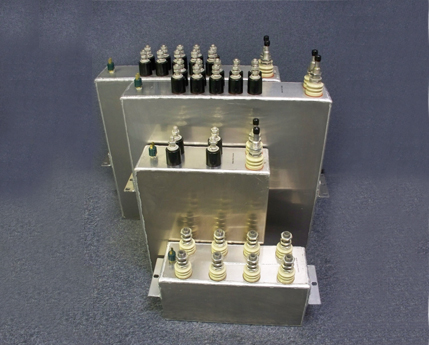

Medium-frequency water-cooled capacitors are designed to handle frequencies between 50 Hz to 20 kHz. These capacitors are used in applications such as welding machines, high-frequency heating equipment, and induction heating systems. The construction of these water-cooled capacitors involves a cylindrical-shaped metal case that is filled with a dielectric material, usually oil or resin. The electrodes are placed in the center of the dielectric material, and the entire unit is submerged in water to cool it.

2) High-Frequency Water-Cooled Capacitor

High-frequency water-cooled capacitors are designed to handle frequencies above 20 kHz. These capacitors are used in applications such as induction heating systems, plasma generators, and medical equipment. The construction of high-frequency water-cooled capacitors involves a cylindrical-shaped metal case that is filled with a dielectric material, usually oil or resin. The electrodes are placed in the center of the dielectric material, and the entire unit is submerged in water to cool it. The high-frequency water-cooled capacitors are also equipped with additional components such as a cooling coil, a water inlet, and a water outlet.

// Applications of Water-Cooled Capacitors

1) Welding Machines

Water cooled capacitors are commonly used in welding machines to stabilize the welding arc and regulate the welding current. These capacitors are used in applications such as arc welding, spot welding, and resistance welding.

2) Induction Heating Systems

Induction heating systems use water-cooled capacitors to produce a high-frequency magnetic field that induces eddy currents in the material being heated. These capacitors are used in applications such as heat treatment, brazing, and soldering.

3) High-Frequency Heating Equipment

High-frequency heating equipment uses water-cooled capacitors to generate an oscillating magnetic field that heats the material being processed. These capacitors are used in applications such as plastic welding, sealing, and cutting.

Pasayadan Electricals is a leading manufacturer and supplier of water-cooled capacitors in India. The company offers a wide range of water-cooled capacitors that are designed to handle various frequencies and power levels. The capacitors manufactured by us are made using high-quality materials and are designed to withstand extreme temperatures and environmental conditions.

We offers both standard and customized water-cooled capacitors to meet the specific needs of its customers. The company has a team of experienced engineers who work closely with its customers to understand their requirements and provide them with the best possible solutions. These capacitors are an essential component in high-power electronics and electrical systems. These capacitors are designed to handle high voltages and currents and are used in various applications such as welding machines, high-frequency heating equipment, and induction heating systems.

We are leading manufacturer of water-cooled capacitors in India. The company offers a wide range of water-cooled capacitors that are designed to handle various frequencies and power levels. The company uses advanced manufacturing techniques and furthermore, the water-cooled capacitors manufactured by Pasayadan Electricals are available in different sizes, shapes, and designs, depending on the specific requirements of the customers. They are made using high-quality materials that ensure durability and reliability in harsh environments. These capacitors have a long lifespan, require minimal maintenance, and are designed to operate at high temperatures without overheating.

We also offers after-sales support, including installation, commissioning, and maintenance services, to ensure that their customers get the best possible performance from their water-cooled capacitors. The company has a team of experienced technicians who provide timely and efficient support to their customers. As a company we strong focus on quality, and its products are tested at every stage of the manufacturing process to ensure that they meet the highest quality standards. The company has implemented a strict quality control system that ensures that its products are of consistent quality and meet the requirements of its customers.

We also provide our total range of products ie. Water cooled capacitor, Medium frequency water cooled capacitor, High frequency water cooled capacitor and different types of capacitors in Pune, Kolhapur, Maharashtra, India

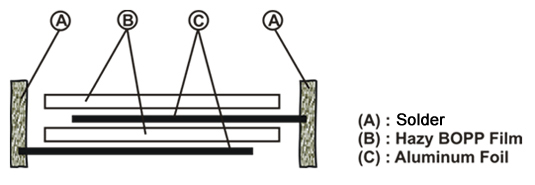

These are designed for use in Induction Heating / Melting Plants For Power Factor Improvement. In Manufacturing Special Polypropylene Film, High purity grade Aluminum Foil and Non PCB Oil is used.

High Grade Copper Pipes are used for Water Cooling. Aluminum / Brass / SS (Stainless Steel) Containers are used according to Frequencies. Also Protection Switches (Thermal / Pressure) provided on request. The losses of our Water Cooled Capacitors are extremely low. The performance of these capacitors, demand extreme levels of Reliability, Safety and Life expectancy.

| Technical Specifications | |

| Rated KVAR | Up to 8400 KVAr (Special Ratings are also available on request ) |

| Rated Voltage | Up to 5000 Volts AC |

| Rated Frequency | Up to 50,000 Hz |

| Tapings | Tapped / Untapped |

| Cooling | Water Cooled / Air Cooled |

| Casing | Aluminum / Brass / S. S. |

| Mounting | Vertical / Horizontal |

| Protection | Thermal & Over Pressure Cut – Off Switch |

| IS Slanders | As per IEC : 60110 (Part 1), IS : 9251 |

- Raw Material : All major Raw Material is Imported like

- Aluminum Foil : Soft Annealed High Purity Aluminum foil (As Electrode).

- Non PCB Oil : The Insulating Oil is very high Thermal Stability‚ These are Non - PCB, Non – Toxic and Bio - Degradable. High Flash Point (146oC)‚ High Fire Point (154oC). Good Hydrogen gas absorbing Capacity and Excellent Heat Transfer Co – Efficient Characteristics.

- Tin - Lead & Tin - Zink : Highly pure Tin - Zink & Tin - Lead with Special Combination Percentage.

- Aluminum Sheet : High Pure Aluminum Sheet for Container.

- Brass Stud : CNC Turned Extreme Quality Brass Studs using Electrical Grade Brass Material.

- Insulating / Wrapping Paper : Electrical Insulating Grade Insulating / Raping Paper.

Aluminum Foil

Polypropylene Film

Brass Stud

Numbers of elements are interconnected in series - parallel combination depending on KVAr and Voltage rating of the Capacitor.

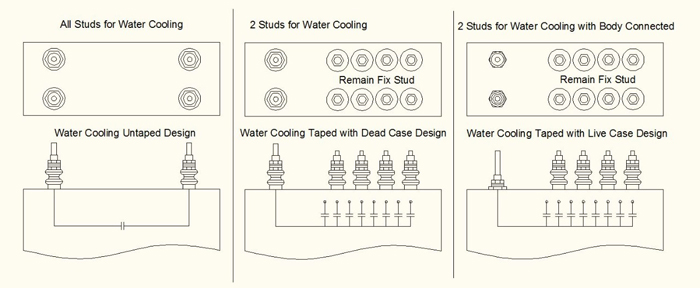

- Water Cooling Taped with Live Case Design

- Water Cooling Taped with Dead Case Design

- Water Cooling Untaped Design

Rated water flow should be minimum 5 L/min. Maximum pressure drop of 140 m bars. Also In–let water temperature should not exceed 35oC. Difference between the in-let & out-let water temperature should be around 10oC

We provide Thermal / Pressure Switch for capacitor. Temperature / case over–heating and trip the system in case of heating beyond preset limits‚ to prevent capacitor failure.

- Each & every Capacitor is Routine test is carried out according to IEC 60110 (Part 1) / IS 9251.

- Capacitance Measurement.

- Dielectric Loss angle Measurement.

- Voltage test between terminals

- Voltage test between terminals & container

- Sealing Test

- Safety – Thermal / Over pressure Dis - connector Switch is provided with normally closed contact.

- Dimensional Verification